Liquid Filter Cartridges

Liquid Filter Elements

Through decades of experience in the oil and gas industry, we understand that there are many unique needs. Applications and contaminants vary, and we approach every filter cartridge selection differently. We base our solutions on the specific need and collaborate closely with each customer. Explore our wide range of pleated and depth liquid filtration cartridges.

Depth Style Liquid Filter Cartridges

Jonell Systems depth style liquid filter elements are carefully designed for the removal of contaminants from a liquid stream. Through the use of a variety of highly compatible medias in a varying scale of fiber diameters, our graded density depth style designs provide the optimum combination of flow characteristics and solid contaminant holding capability.

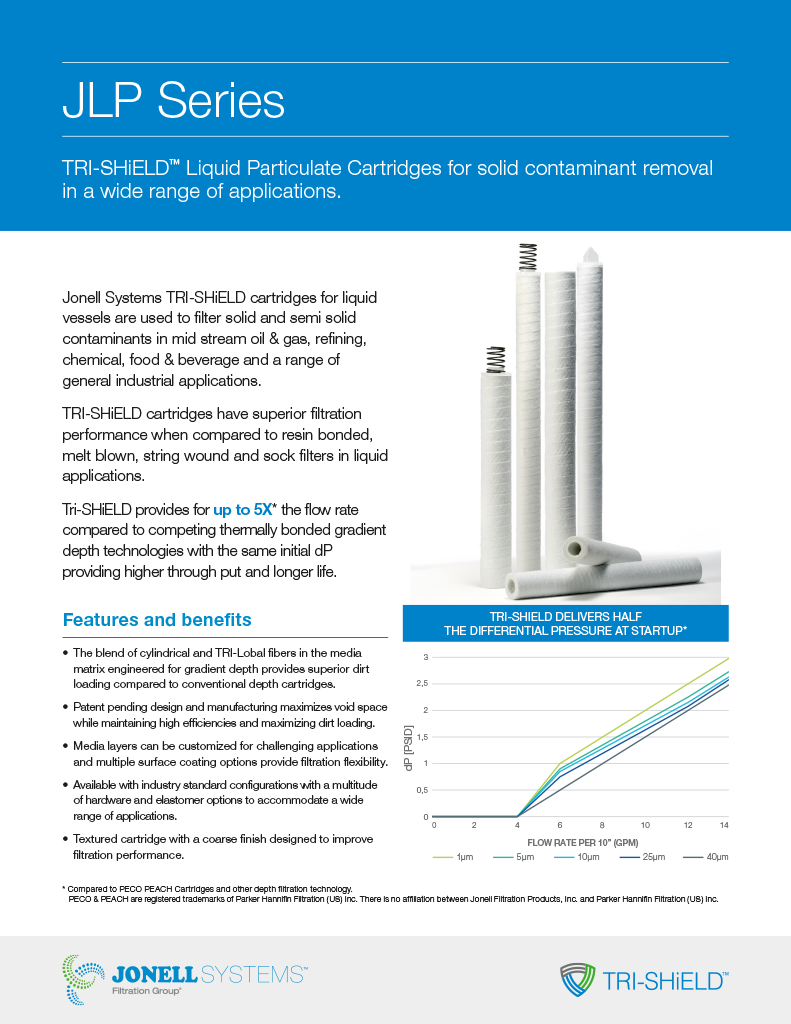

TRI-SHiELD™ Series (JLP)

Tri-Lobal High Efficiency Depth Filter Elements

The unique engineered blend of multiple fibers sizes and shapes, including Tri-Lobal, are specifically layered in an advanced spiral construction. This process gives TRI-SHiELD superior dirt loading and high efficiency when compared to traditional depth filtration medias.

FluiSock™ Series (JB)

Rolled Sock Style Filter Elements

FluiSock Series Rolled Filters are rolled type filter elements manufactured using specific blends of media designed for a range of applications in the oil and gas industry.

The Jonell Systems FluiSock series is one of the oldest, most economical, and most trusted filtration technologies in the oil and gas industry today.

JPD Series

Polypropylene Depth Style Cartridges

JPD Series large diameter coreless depth cartridges deliver cost effective performance at low pressure drop in liquid base applications with high flow rates.

These are well suited to mid-steam applications in oil and gas industry to capture solid and semi solid particulates within the filter media to deliver reliable, cost effective filtration.

ResDEP™ Series (JRB)

Bonded Filter Elements

ResDEP Bonded Filter Elements have a unique proprietary two-stage filtration design to maximize particle retention and service life in viscous fluid filtration applications.

An outer spiral pre-filter wrap, made from a blend of polyester and acrylic fibers, increases cartridge strength and eliminates residual debris associated with conventional or machined grooved resin bonded cartridges.

ToughWound™ Series (JJ)

String Wound Filter Elements

ToughWound String Wound Filter Elements are low cost nominal filtration technologies which are very effective for use in a variety of contaminants from water, vegetable oils, beverages, and other fluids.

String wound filters are among the most common type of liquid filters used in the world today.

JMB™ Series

Melt Blown Filter Elements

JMB Melt Blown Filter Elements are made of a polypropylene resin using no binders, lubricants, or antistatic agents in our manufacturing process.

JMB polypropylene filters have been tested and certified under ANSI/NSF Standard 42 for material requirements only.

The inert polypropylene resin provides exceptional chemical compatibility to handle a wide range of process fluids.

BiDEP™ Series

High Efficiency Synthetic Bi-Component Filter Elements

he BiDEP series rigid filter cartridges are made of high efficiency, thermally bonded, bi-component fibers.

The unique fiber-to-fiber bond forms a three dimensional fiber network that offers a high tolerance to differential pressures.

This feature also prevents changes in the fiber matrix throughout the life of the fiber allowing for precise filtration and eliminating filter unloading.

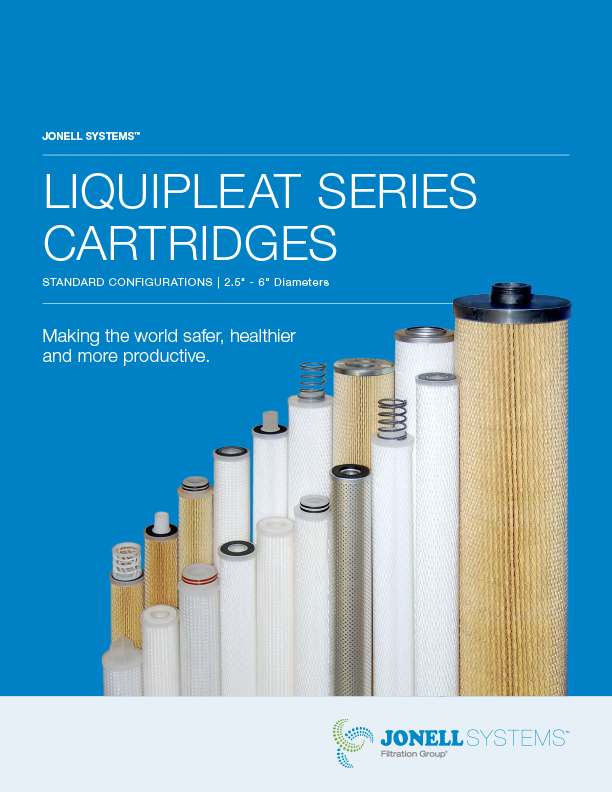

Pleated Style Liquid Filter Cartridges

LiquiPleat™ Series

Our pleated style liquid filter cartridges are high surface area high efficiency filter elements specifically designed for the removal of contaminants in critical liquid applications.

They are available in various grades of absolute rated high performance media with hardware customizable to suit your application

LiquiPleat™ HT Series

The Jonell Systems High Temperature (HT) Series cartridges have been designed to filter solid particulates down to 0.5 microns from liquid feed streams with a maximum continuous temperature of 425 deg F in refinery applications.

This disposable cartridge eliminates the need to clean reusable filters and maintains high efficiencies throughout the process to make the world safer, healthier and more productive. This cartridge provides refineries with an effective and efficient alternative to string wound elements which often cause contamination downstream and are not ideal for fine filtration.

Available in a wide range of cartridge sizes from small diameter (2.5” OD) to large diameter (6+” OD) to retrofit in existing vessels or fit new vessels designed for the application including high flows.

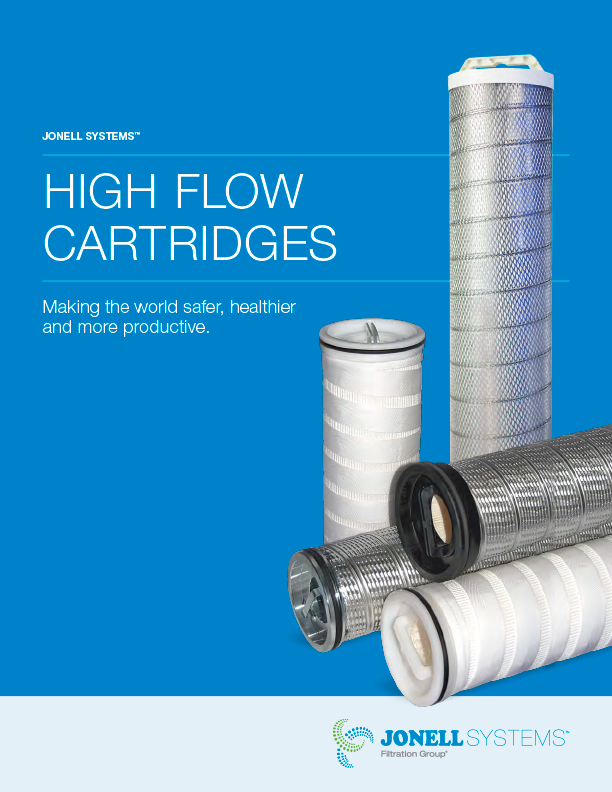

LiquiPleat™ HF Series

(JHF)

High Flow Filter Elements

LiquiPleat HF Series elements are large diameter, high efficiency, inside-to-outside flow liquid elements designed for applications with large flow requirements.

Available in various grades of absolute rated high performance media with hardware customizable to suit your specific applications. The large surface area pleated media cartridges are designed to provide the optimum combination of particle removal efficiency and contaminant holding capability.

LiquiPleat™ HF XTR Series (JHFO)

High Flow Filter Elements

LiquiPleat HF XTR Series filters are large diameter elements designed for ultra-high flow applications.

These high efficiency elements are designed with a double O-ring sealing system for high liquid flow outside-to-inside direction requirements.

Available in various grades of absolute rated high performance media to suite your specific application.

LiquiPleat™ A Series (JPMA)

Cotton Filter Elements

LiquiPleat A Series Cotton Filters are used in specialized applications, such as gas sweetening processes that require removal of organic and inorganic solids from amine systems.

Our LiquiPleat A Series filters provides increase efficiency and surface area over traditional cotton string wound filter technologies while maintaining the temperature and compatibility characteristics of cotton media.

LiquiPleat™ E Series (JPME)

Polyester Synthetic Filter Elements

LiquiPleat E Series polyester filters are pleated elements designed for applications with large flow and contaminant requirements.

LiquiPleat E Series filters are available in various grades and configurations of high performance polyester with hardware to suit your application.

LiquiPleat™ P Series (JPMP)

Polypropylene Synthetic Filter Elements

LiquiPleat P Series polypropylene filters are pleated liquid filtration elements designed for applications with large flow and contaminant requirements.

LiquiPleat P synthetic filters are available in various grades and configurations of high performance polypropylene with hardware to suite your applications.

LiquiPleat™ G Series (JPMG)

Fiberglass Pleated Filter Elements

LiquiPleat G Series Microfiberglass filters are pleated liquid filtration elements designed for applications with large flow and contaminant requirements.

LiquiPleat G Series filters are high efficiency elements available in various grades and configurations of high performance microfiberglass media with hardware to suit your application.

LiquiPleat™ C Series (JPMC)

Resin Bonded Cellulose Filter Elements

LiquiPleat C Series resin bonded cellulose filters are an economical choice for applications such as glycol filtration and lubricating oil where nominal filtration is desired.

Economical filter that provides increased surface area over traditional stringwound and meltblown cartridges.

LiquiPleat™ K Series (JPMK)

Polycell™ Media Filter Elements

LiquiPleat K Series Media Hybrid Liquid Filter Elements are designed using our proprietary K media blend which consists of bonded polyester and cellulose fibers.

This special blend of media provides some of the structural and compatibility advantages of standard polyester liquid filter elements at a cost closer to that of an economy level cellulose filter.

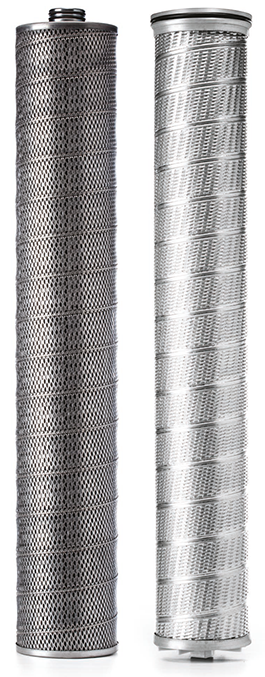

LiquiPleat™ SS Series (JPSS)

Metallic Filter Elements

Pleated Metal Liquid Filter Elements are the ultimate in durability and chemical compatibility.

These elements can be used in ultra-high temperature applications and are often backwashed and re-used multiple times before discarding.

LiquiPleat™ N Series (JPMN)

Nylon Pleated Filter Elements

LiquiPleat N Series Nylon filters are pleated liquid filtration elements designed for applications with specific chemical compatibility restraints.

LiquiPleat N Series filters are available in various grades and configurations of high performance nylon media with hardware options to suit your specific applications.

LiquiPleat™ GX Series (JPMGX)

Nomex/Fiberglass Pleated Filter Elements

LiquiPleat GX Series filters are constructed of a combination of Nomex and Microfiberglass medias specifically designed for higher temperature rated applications.

Available in various grades of high performance media with hardware options to suit your specific application.

LiquiPleat™ ME Series (JME)

Molded-End Filter Elements

LiquiPleat ME Series filter elements are molded from high quality plastisol that seals the ends of the elements while acting as a gasket against the sealing plates in the filter housing.

A wide selection of media is available, including: cotton, rayon, polyester, polypropylene, nylon, Teflon®, Nomex®, and fiberglass.

LiquiPleat™ H Series (JH)

Hydraulic Filter Elements

LiquiPleat H Series Hydraulic Filter Elements are heavy duty; high collapse pressure elements designed for use in hydraulic service and are inert to most aromatic compounds.

Available in various grades of high performance media with hardware customizable to suit your specific application.

Two-Phase Liquid Separation

Two-phase liquid separation elements separate and remove undesired free aqueous or non-aqueous droplets from a liquid stream.

Our two-phase liquid separation product line contains a large assortment of coalescing filters and horizontal re-packs, as well as, liquid separating elements.

Filters are available in fiberglass and silicone impregnated cellulose designs as well as synthetic, stainless steel, and Teflon® materials for use in caustic service.

Phase-LOK™ S Series (JS)

Pleated Silicone Impregnated Cellulose Separator

Phase-LOK S Series Pleated Silicone Impregnated Cellulose Separator Elements incorporate specially treated silicone impregnated cellulose to produce a hydrophobic media that repels water while allowing hydrocarbons to pass through.

Due to the filtration level achieved in the coalescer stage, they rarely foul with solids and typically require replacement only every second or third coalescer change to a maximum service life of one year.

Phase-LOK™ T Series (JST)

Teflon® Phase Separator Filter Elements

Phase-LOK T Series Phase Separator Elements are constructed of Teflon® coated stainless steel screen. Similar to the S Series, Phase-LOK T hydrophobic Teflon media repels water while allowing hydrocarbons to pass through.

Due to the filtration level achieved in the coalescer stage, T series elements rarely foul with solid contaminants, can withstand a wide pH range, and are highly compatible in most applications.

Facet InterPhase™ SS Series

Synthetic Separator Filter Elements

Facet InterPhase SS Series Separator Elements are hydrophobic and repel water droplets that form while passing through the liquid/liquid coalescers. They perform exceptionally well in a broad range of liquid applications and are more efficient and cost less than Teflon® coated separators.

These elements provide excellent chemical compatibility and can also be cleaned and reused.

PhasePUR™ G Series (JC) (JCP)

Fiberglass Coalescing Elements

PhasePUR G Series Fiberglass Phase Coalescing Filter Elements are designed to coalesce two immiscible liquid phases within a stream to aid separation. These cartridges are also highly efficient particulate filters.

These elements should always be protected by a pre-filter. In installations where no pre-filter exists, the JCP version uses an additional pleated section on the upstream side of the coalescer media to extend the effective operating life and protect the coalescing media.

PhasePUR™ E Series

Synthetic Phase Coalescing Filter Elements

PhasePUR E Series synthetic liquid/liquid coalescing filters were developed for applications where glass media is not compatible.

Utilizing Jonell Systems’ TRI-SHiELD™ synthetic polyester coalescing media, these filters are designed to remove water from fuels, lube oils, condensates, and other hydrocarbons.

JPAKS™ Series

Depth Style Phase Coalescing Wafer Packs

JPAKS Series Liquid Coalescing Wafer Packs are designed in various materials and media densities specifically engineered for the separation of immiscible liquids.

Through controlled fiber sizes and carefully distributed media densities, Jonell Systems’ JPAKS provide maximum coalescing surface area to ensure the optimum fluid contact time prior to gravitational phase separation of coalesced fluids.

HydroSorb™ Series (JPMWA)

Water Absorption Filters

HydroSorb Series Water Absorption Elements filter solid particulates and absorb water from petroleum based fluids.

Solid particulates are removed by pleated cellulose filter media which is bonded with water absorbing hydrophilic media.