High Flow Technology

Liquid Filtration Solutions

High flow technology solutions for high performance filtration.

As the oil and gas industry strives to increase productivity, safety, and economics in all equipment designs, filtration is no different. There is a pressing need to filter liquid feeds at high flow rates to keep pace with scaling processing capabilities and run feeds without slowing down the process.

Filtration solutions are necessary to remove harmful contaminants that can foul and damage downstream equipment or produce off-spec products. Jonell Systems has proven, field-tested high flow filtration technology, designed to provide quality filtration at higher flow rates.

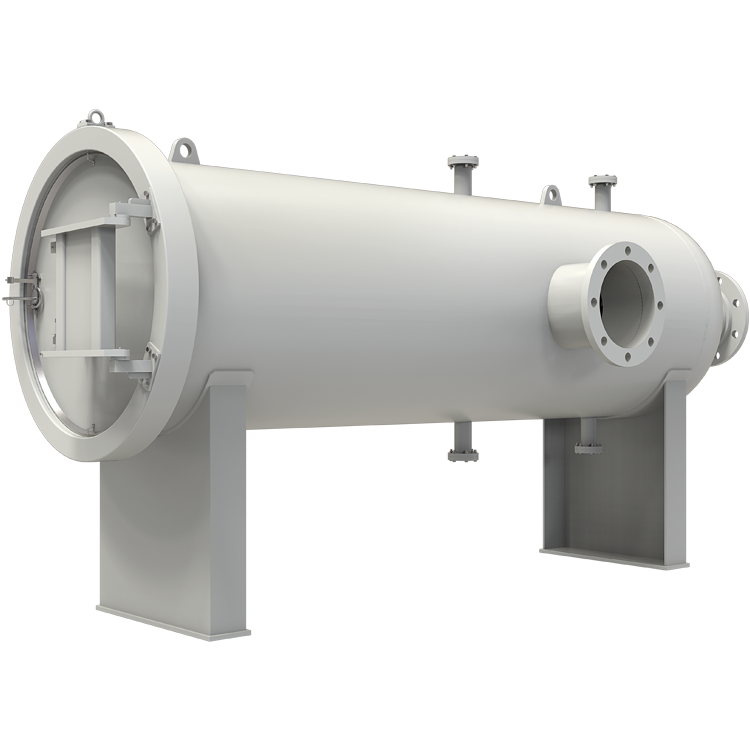

Built to ASME Section VIII Div. 1 Code, available in both vertical and horizontal configurations, the application will determine the design.

Jonell Systems’ High Flow Filtration Solutions are designed to:

• Improve Product Quality

• Increase Production Yields

• Extend Life of Filtration System

• Reduce Labor Requirements and Costs

• Protect Downstream Equipment

• Reduce Maintenance Costs

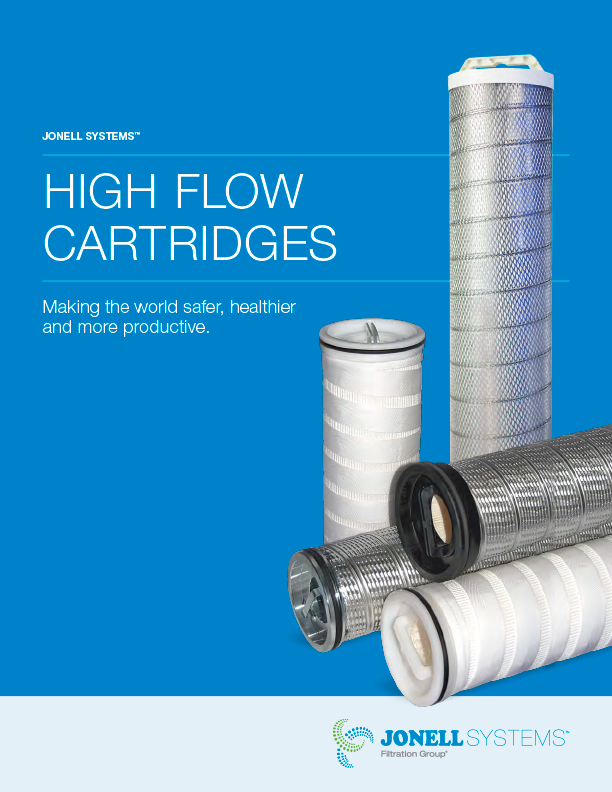

High Flow Technology Filter Cartridges

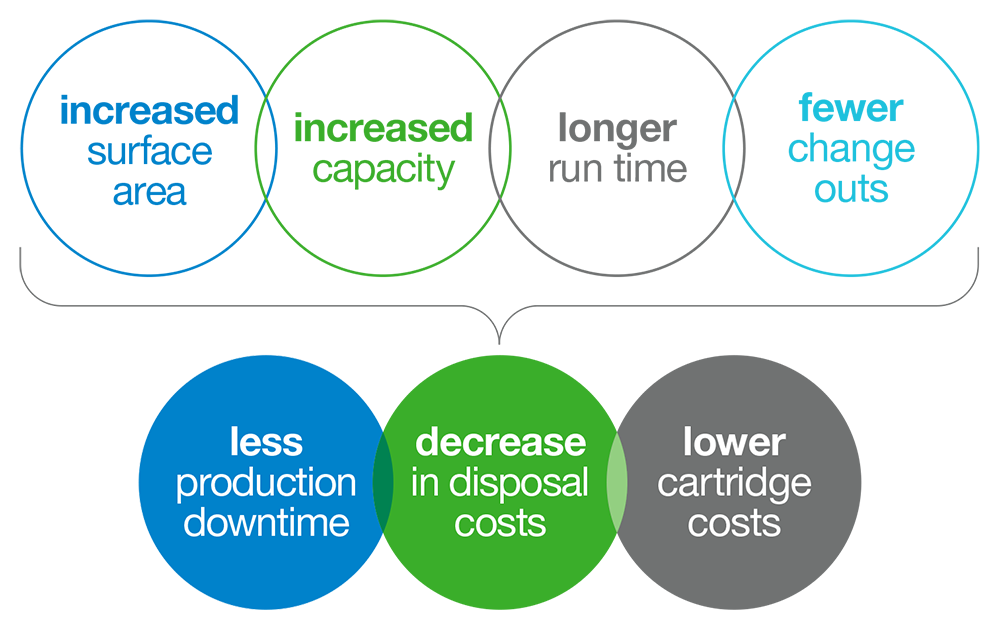

High flow cartridges are offered with a standard pleat configuration as well as a W-pleat configuration for increased filtration surface area. Increased surface area and larger throughput creates smaller housing footprints utilizing fewer cartridges. Utilizing a toolless O-ring design ensures a fast, hassle free, positive seal during each changeout. One six-inch diameter cartridge (60″ and 80″ long) can handle up to 500 gpm based on 1 cP viscosity.

Jonell Systems’ media has been engineered for high efficiency removal of contaminates and superior dirt loading capabilities. Our media and hardware options allow us to manufacture solutions for a wide range of applications.

Jonell Systems High Flow technology configurations

M Series High Flow Housing+ JHFO Cartridges

Jonell Systems M series multi-cartridge housing utilizes a full length riser post to properly align cartridges during installation and ensure a positive seal.

Safety is at the forefront in the M Series design. With cartridges located at the front face of the vessel it provides convenient, operator friendly, and most importantly safe access by eliminating confined space entry concerns.

| Features | Benefits | Advantages |

|---|---|---|

| Large diameter and optimal pleat density | Greater than 95% increase in surface area* | Higher processing capability with up to 5X greater flow |

| Out-to-in flow with more open pleat pack | Optimal flow profile & high effective surface area | High Dirt Loading |

| Smaller diameter vessel* | Smaller footprint | Lower capital cost |

| Increased surface area of cartridge | Lower flux rates | Longer run times, fewer changeouts, less maintenance costs |

| Double O-ring Seal | Positive seal with no bypass | High product quality |

HF Series High Flow technology Housing + JHF Cartridges

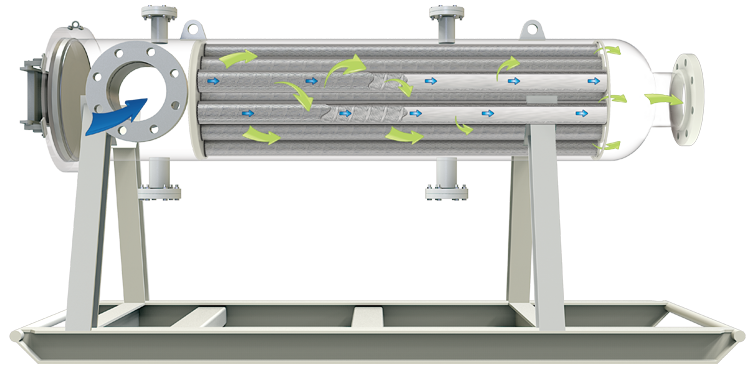

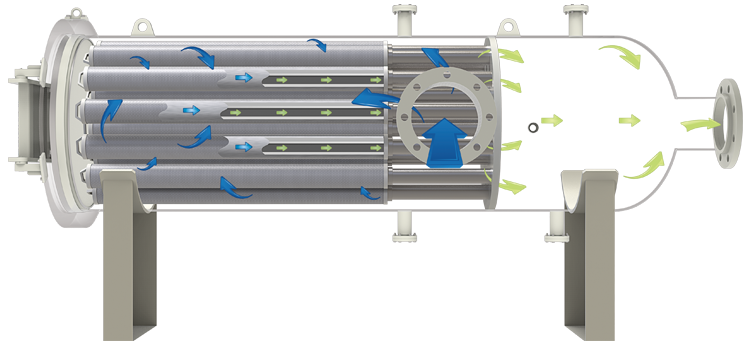

HF high flow single and multiple cartridge filter housings have been designed specifically for high throughput and reduced CAPEX. Housings can be constructed in either a horizontal or vertical orientation depending on the availability of space.

The standard horizontal configuration of this housing minimizes pressure drop and makes cartridge change-out much easier than standard designs.

| Features | Benefits | Advantages |

|---|---|---|

| Large diameter cartridge | Up to 70% increase in surface area* | Higher processing capability with up to 3X greater flow |

| In-to-out flow | Contaminant contained within the cartridge | Ability to recover catalyst (and other particulates) to reuse if needed |

| Smaller diameter vessel* | Smaller footprint | Lower capital cost |

| Increased surface area of cartridge | Lower flux rates | Longer run times, fewer changeouts, less maintenance costs |

| Single O-ring Seal | Positive seal with no bypass | High product quality |