Systems

Filtration Systems

Our oil and gas filtration systems lead the industry in quality, reliability, and longevity. We understand that every process, application and scenario is unique which is why we work closely with our customers to design and customize our filtration systems and solutions.

The contaminants, process and application determines the method of filtration. Our wide range of cartridge based solutions and systems allow us to recommend the best fit filtration solution for your application.

Mechanical Filtration Systems

ProGuard – Automatic Backflushing Filter

The ProGuard Series automatic backflushing filter is specifically designed for the robust requirements of refinery streams. The filter is designed to minimize the backflush volumes while effectively removing contaminants.

- Used in hydrocarbon refining, process water, coke cutting water

- Continuous filtration with automatic self cleaning

- Large filter surface area from pleated mesh filter elements

- Wedge wire elements are also available

- Low backflush rates and optimal cleaning of the filter elements improve filtration efficiency

- Easy to service

- Modular design to accommodate wide range of process flow rates

- Filter ratings from 25 micron absolute and larger

- ASME Code, Section VIII, Division 1

- Optional CE or CRN certification available

- Worldwide network of distribution and service agents

Seawater Filters

The seawater filter is a back flushing filter for the removal of solid contaminants from water and emulsions. With flexible designs to suit your application, this filter is a reliable and cost-effective choice for the filtration of seawater to protect your equipment.

• Compact and lightweight — ideal for fixed and floating platforms

• Exceptionally reliable — increased uptime and lower running costs

• Flexible design — easily integrated into new and existing projects

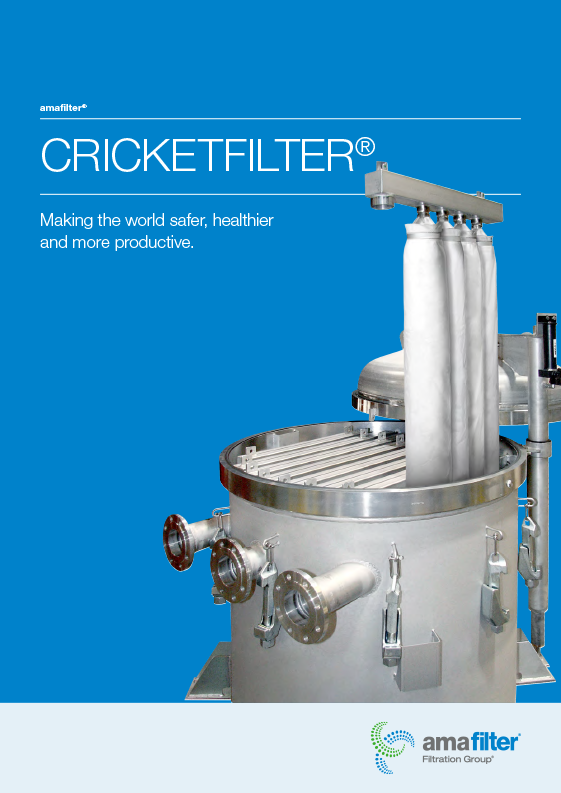

Cricketfilters

The Cricketfilter technology has been developed to separate solid particles from a liquid such that the solid particles can be discharged if dry matter or a slurry. Liquid losses are kept to an absolute minimum.

- Side outlet, ensuring a completely drainable septum.

- Improve safety by reducing the use of bag filters.

- Eliminate the risk of opening bag filter housings.

- Space saving through an excellent surface/volume ratio because of unique Cricket element design.

- Improved cloth mounting thanks to use of the proven Cricket type I element construction.

- Easy to connect several filters, saving space and investment.

- Easy to automate, therefore low maintenance required.

- Very high cleanability due to fewer internal parts.

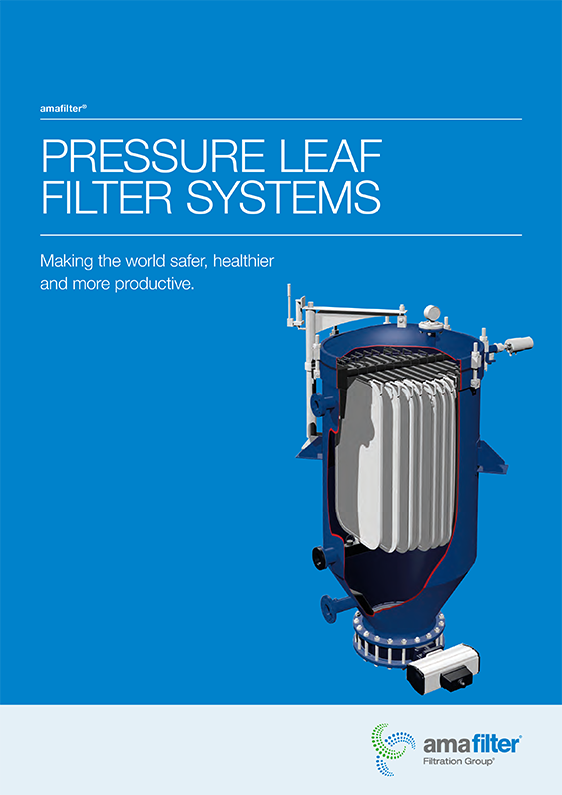

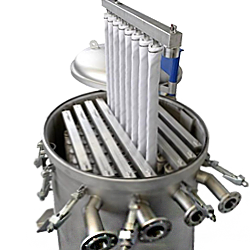

Pressure Leaf Filter Systems

Our pressure leaf filter systems are designed to maximize the filtration surface area of the filter leaves and offer optimal bulk filtration in the smallest footprint.

The pressure leaf filter systems produce high filtrate clarity. Different types of filter aids can be used in our pressure leaf

filters to improve filtrate quality.

- Proven technology. Fully automated, ensures safety.

- Small footprint required, maximized space.

- Easy access to clean the filter leaves and for removal of cake.

- Full automation; limited maintenance and lower operational costs.

- Short regeneration time between filtration cycles reduces operating costs as the filter can filtrate for longer periods without disruptions.

- No rotating parts, keeping maintenance to minimum.

- Reinforced pressure filter leaves provide extended lifetime.

- Specifically designed self sealing cover gaskets for a perfect sealing solution and maximum safety.