Liquid Filter Housings

Liquid Filter Housings

Our liquid filter housings lead the industry in quality, reliability, and longevity. Each filter housing is built to ASME Code Section VIII Div. 1. We custom-design housings to meet international codes and regulation requirements. We understand that every process and scenario is unique which is why we work closely with our customers to design and customize our vessels. These are extensively used in process applications in refining, chemical and oil & gas industry.

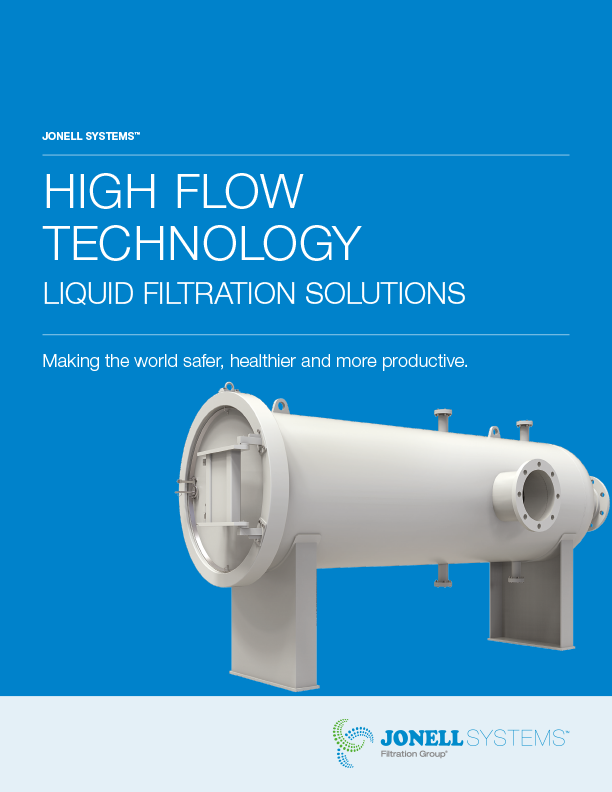

Liquid Filtration

High Flow

HF Series

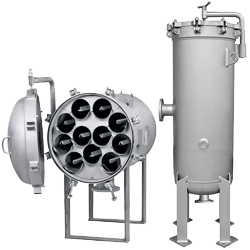

HF high flow single and multiple cartridge filter housings have been designed specifically for high throughput and reduced CAPEX. Housings can be constructed in either a horizontal or vertical orientation depending on the availability of space.

The standard horizontal configuration of this housing minimizes pressure drop and makes cartridge change-out much easier than standard designs.

- The HF series high flow single and multiple cartridge filter housings have been designed specifically for high output while occupying only a small footprint area.

- Housings can be constructed in either a horizontal or vertical orientation depending on the availability of space.

- The standard horizontal configuration of this housing minimizes pressure drop and makes cartridge element change-out much easier.

- Typical markets for the HF series filter housings include: food & beverage, chemical, refinery processes, oil & gas, water filtration, pulp & paper, metal finishing and power generation.

M Series

The M series horizontal or vertical, multi-cartridge housing has the unique design of assuring the elements are seated in the mount receptacles before the closure can be tightened. This prevents improper reseating of cartridges prior to being placed into service and also keeps possible system back pressure from dislodging the elements from their respective seals. The design also includes an internal element support plate to aid in dirty element removal without damage to element supports from dead weight deflection.

- Housings contain twice as much surface area for the same diameter vessel as competitive products

- Unique guide tubes for easy, accurate installation of cartridges Dual O-Rings on elements seal themselves as the vessel cover is tightened, insuring no liquid bypass. Springs or cups are not used

- Gauge ports and drain ports are pre-tapped making gauges and valves easy to install

- Optional air eliminator that releases air from the vessel which eliminates manual venting.

- Automatic venting insures full use of the available filter surface area

- Vessels meet ASME Code Section VIII, Division I which insures premium material and construct

Single & Multiple Cartridge Liquid Filter Housings

A Series

These filter housings provide operators with highly efficient liquid filtration, matched to their specific operating requirements. Flow rates, operating pressures and temperatures, plus the fluid being filtered are all taken into consideration when selecting the right filter for the job.

- Sizes from 4 to 81 cartridges

- 200 to 1440 psi working pressure

- Aqueous flow rates to 648 gpm

- Bolted closure for safe, fast cartridge replacement

- Multiple O-ring closure seals available

- ASME code construction available

P Series

- Designed for long life, these multi-purpose, high flow, cartridge filter housings offer exceptional value.

- The vessels accept cartridges that are 44 inch long, by 6 inches outside diameter, by 3.5 inches inside diameter.

- All P series filter housings are designed to ASME code standards for added quality assurance.

- Housings are available in horizontal design and vertical configurations. They can be used in many applications such as lube and hydraulic oils, oil & water filtration, petroleum refining applications, pulp & paper industry, and power generation.

N Series

The N series high-flow, multi-cartridge filter housings are designed for long life and exceptional value. These multipurpose, high flow, 150 psi filters are built with our continued commitment to quality that has made us a leader in filtration systems worldwide.

- N series filter housings have numerous, customizable options and features including sizes ranging from 22 to 230 cartridge models.

- Housing construction materials are carbon steel (NC series) or 316 stainless steel (NU series).

- All N series filters are built to ASME code design standards for added quality assurance.

Basket Strainers Housings

The K series fabricated, in-line, basket strainers effectively remove dirt, pipe scale, and other contaminants from process liquids such as water, chemical and petroleum products.

The standard housings contain stainless steel baskets which have many customizable features such as material of construction, closure style, pressure rating, connection style and size, and support legs.

1 Series – Filters for Liquid and Gas Applications

1L Series

- Available in 1, 2, 3 or 4 cartridge models

- 200 psi working pressure

- Carbon steel or stainless steel construction

- T-Handle closure nut

- Buna shell gasket

- One piece body construction

- 1” Internal pipe thread inlet/outlet connections

- 1/8” Internal pipe thread drain is standard

- Useful for gas or fluid filtration

- Water flow rates to 24 gpm

- Glycol flow rates to 15 gpm

1S Series

- Available in 1, 2, 3 or 4 cartridge length models

- 2000 psi working pressure

- Cast carbon steel head

- Carbon steel or epoxy lined carbon steel body

- Brass or carbon steel internals

- Grooved closure

- Buna gasket

- Gas or fluid filtration

- Water flow rates to 24 gpm

- Glycol flow rates to 15 gpm

- 1” internal pipe thread inlet/outlet connections

- 1/4” internal pipe thread drain is standard

- Optional 1/4” internal pipe thread differential pressure ports

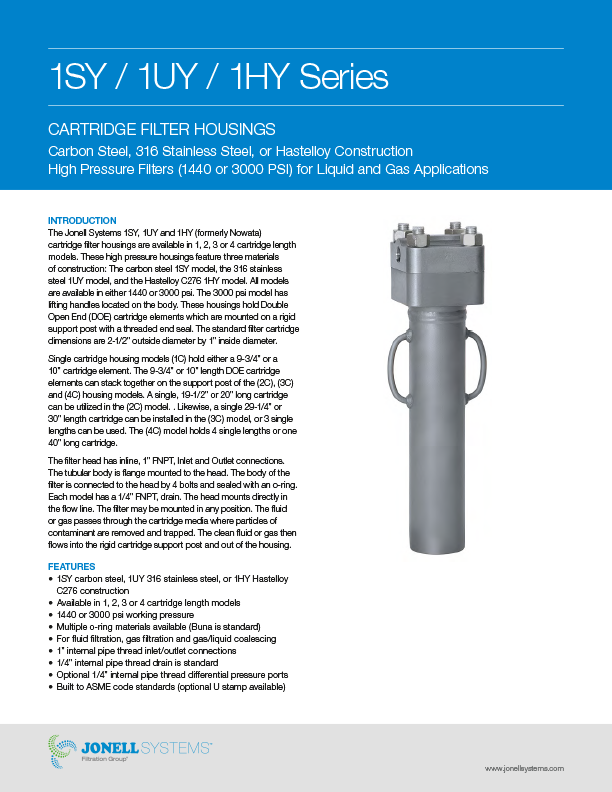

1SY / 1UY / 1 HY Series

- Available in 1, 2, 3 or 4 cartridge length models

- 1440 or 3000 psi working pressure

- Multiple o-ring materials available (Buna is standard)

- For fluid filtration, gas filtration and gas/liquid coalescing

- 1” internal pipe thread inlet/outlet connections 1/4” internal pipe thread drain is standard

- Optional 1/4” internal pipe thread differential pressure ports

- Built to ASME code standards (optional U stamp available)

1U Series

- Available in 1, 2, 3 or 4 cartridge length models

- 2000 psi working pressure

- Cast 316 stainless steel head

- 316 stainless steel or epoxy lined carbon steel body

- 316 stainless steel internals

- Grooved closure

- Buna gasket

- Gas or fluid filtration

- Water flow rates to 24 gpm

- 1” Internal pipe thread inlet/outlet connections

- 1/4” Internal pipe thread drain is standard

- Optional 1/4” internal pipe thread differential pressure ports

Adsorbents

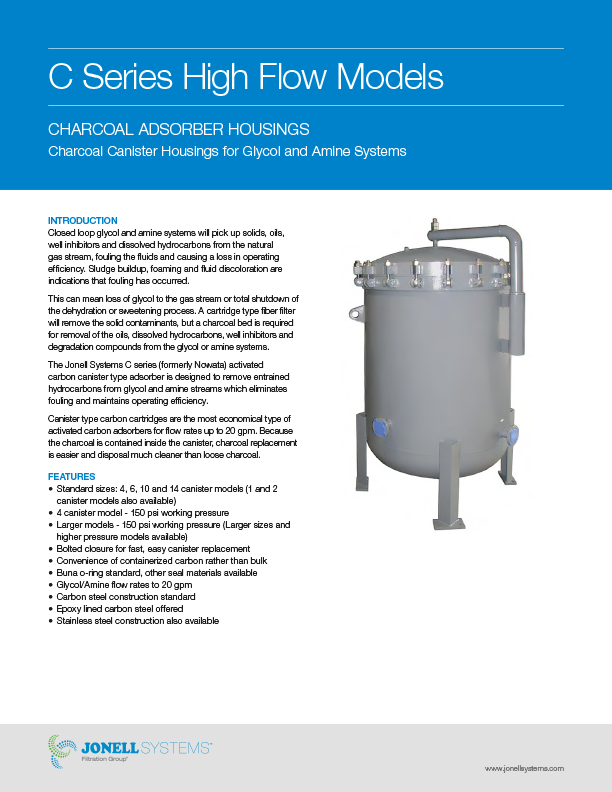

C Series – Activated Carbon Canister Housings

The C series activated carbon canister type adsorber is designed to remove entrained hydrocarbons from glycol and amine streams which eliminates fouling and maintains operating efficiency. Canister type carbon cartridges are the most economical type of activated carbon adsorbers for flow rates up to 20 gpm. Because the charcoal is contained inside the canister, charcoal replacement is easier and disposal much cleaner than loose charcoal.

Mercaptan Removal Carbons

- Ultra high process purification for seals gases

- Mercaptan Control, Moisture Control, H2S Elimination

- High packing density leads to improved adsorbption capacity

- Ultra-high purity sales gases

- High integrity Carbon leads to less