Gas Filter Cartridges

Gas Filter Cartridges

Through decades of experience in the oil and gas industry, we understand that there are many unique gas filtration application needs. Applications and contaminants vary, and we approach every filter cartridge solution based on the specific needs of the application.

With our wide range of cartridges designed in pleated and depth style for solids removal and coalescing, we can help you with your gas filtration challenge.

Depth Style Gas Filter Cartridges

Jonell Systems depth style filter elements are specifically designed for gas filtration and liquid coalescing. Through the use of a variety of highly compatible media in a varying scale of fiber diameters, our graded density style of filter designs provide the optimum combination of solid contaminant holding and liquid particle coalescing capability.

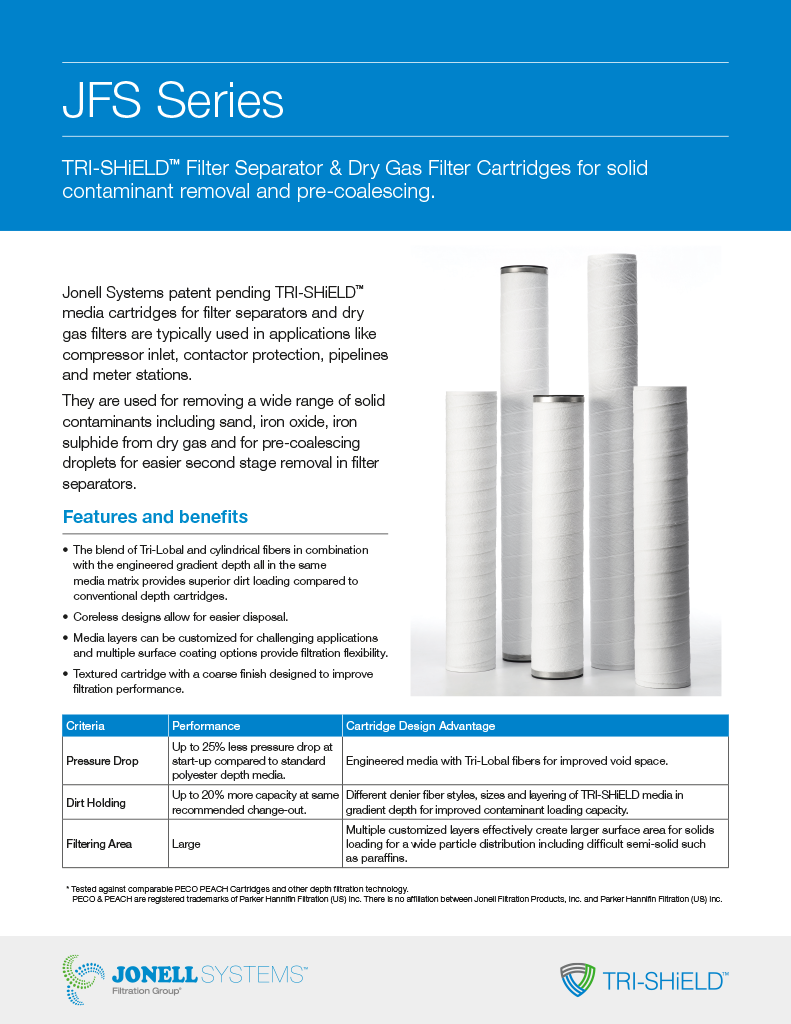

TRI-SHiELD Series (JFS)

Tri-Lobal High Efficiency Depth Filter Elements

TRI-SHiELD™ filters are our latest innovation in improved depth style filtration.

The unique engineered blend of multiple fibers sizes and shapes, including Tri-Lobal, are specifically layered in an advanced spiral construction. This process gives TRI-SHiELD superior dirt loading and high efficiency when compared to traditional depth filtration medias.

Each layer performs a specific contaminant management function which gives us the ability to engineer different layers of media even for the most challenging applications.

Depth-LOK™ Series (JFG)

Fiberglass Filter Elements

The Depth-LOK Series Fiberglass Gas Filters are gradient depth style filter/separator elements.

They are designed for the removal of 1.0 µm particles from a gas stream, as well as, coalescing liquids for easier removal. The Depth-LOK series is one of the most popular industry filters and is regarded as an industry work horse.

Depth-LOK™ XTR Series (JMG)

Micro-Fiberglass Filter Elements

Depth-LOK XTR Series Fine Micro-Fiberglass filters are designed for the removal of ultra-fine 0.3 micron particles such as iron sulfides (FeS) from a gas stream, as well as, coalescing liquids.

When an absolute 0.3 micron rating of solids is required in a depth style option, the Depth-LOK XTR Series is field tested and proven to do the job.

Depth-LOK™ HT Series (JFGGF)

High Temperature Filter Elements

Depth-LOK HT Series High Temperature Filters are specially designed for ultra-high temperature gas filtration.

By using a depth matrix of heat treated Pyrex glass fibers with high quality stainless steel hardware and high temperature gaskets, the Depth-LOK HT elements can be safely operated in high temperature applications with temperature ranges from 375 deg F to 500 deg F.

Depth-LOK™ Quick-Change Series (JQC)

The Quick-Change series has been designed as an extension to the Jonell Systems Depth-LOK™ product line. The Depth-LOK™ cartridges are designed to provide the optimum combination of solid contaminant holding and liquid contaminant pre-coalescing capability.

Jonell Systems Quick-Change toolless cartridges are built to reduce maintenance downtime with design features like rounded end caps, wide handle grip, high durometer chevron gasket for a positive seal to avoid bypass and effective contaminant removal.

These are replacements for PECO EZ-Align* Series cartridges for the Titan-Purasep* series housings, these cartridges can be easily installed without indexing reducing downtime.

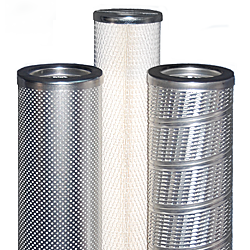

Pleated Style Gas Filter Cartridges

GasPleat™ Series

Our pleated Gas Filtration products are available in a wide variety of material and orientations to provide our customers with optimal filtration control.

In addition to a large assortment of standard part numbers, we can quickly customize a gas filter to suit specific filtration requirements.

GasPleat™ G Series (JPMG)

Microglass Pleated Filter Elements

GasPleat G Series Pleated Microglass Gas Filter Elements are high efficiency cartridges specifically designed for the removal of contaminants in critical gas applications.

They are available in various grades of absolute rated high performance microglass media with hardware customizable to suit your application.

GasPleat™ E Series (JPME)

Polyester Filter Elements

GasPleat E Series Pleated Synthetic Polyester Dry Gas Filter Elements are high efficiency filters specifically designed for the removal of solid particulate contaminants in critical gas applications.

Polyester has excellent use in dry gas applications with exceptional dimensional stability and good resistance to chemicals and abrasion.

They are available in various grades of absolute rated high performance polyester media with hardware customizable to suit your application.

GasPleat™ P Series (JPMP)

Polypropylene Filter Elements

GasPleat P Series Pleated Synthetic Polypropylene Dry Gas Filter Elements are high efficiency filter elements specifically designed for the removal of solid particulate contaminants in critical gas applications.

Polypropylene exhibits excellence resistance to acids, alkalis, and hydrolysis.

They are available in various grades of absolute rated high performance polypropylene media with hardware customizable to suit your application.

GasPleat™ K Series (JPMK)

Bonded Blended Polycell™ Filter Elements

GasPleat K Series bonded blended Polycell filters are designed using our proprietary “K” media blend with consists of bonded polyester and cellulose fibers.

This special blend of media provides some of the structural and compatibility advantages of our tier 1 polyester dry gas filter elements at a cost closer to that of an economy level cellulose filter.

GasPleat™ C Series (JPMC)

Resin Bonded Cellulose Filter Elements

Pleated resin bonded cellulose dry gas filters provide a low cost economical approach to dry gas filtration in non-critical applications.

They are available in various grades of absolute rated high performance media with hardware customizable to suit your application.

GasPleat™ SS Series (JPSS)

Metal Filter Elements

Pleated metal filter elements are the ultimate in durability and chemical compatibility.

These elements can be used in ultra high temperature gas applications and are often backwashed and re-used multiple times before discarded.

GasPleat™ HT Series (JPMG-HT)

High Temperature Gas Filter Elements

GasPleat HT Series High Temperature Pleated Microglass Gas Filter Elements are high efficiency cartridges specifically designed for the removal of contaminants in critical gas applications operating at high temperatures.

They are available in various grades of absolute rated high performance microglass media with tinned carbon steel or high temperature stainless steel hardware.

GasPleat™ SE Series (JSE)

Sewn-End Filter Elements

GasPleat SE Series sewn-end radial fin gas filter elements are designed to replace any manufacture’s elements of this design in particulate removal from a gas stream.

A wide selection of media is available including: cotton, rayon, polyester, polypropylene, nylon, Teflon®, Nomex®, and fiberglass to suit any application

GasPleat™ ME Series (JME)

Molded-End Filter Elements

Jonell Systems molded-end pleated filter elements are designed to replace any manufacturer’s elements of this design in gas service.

The GasPleat ME Series filters are molded from high quality plastisol that seals the ends of the elements while acting as a gasket against the sealing plates in the filter housing.

A wide selection of media is available including cotton, rayon, polyester, polypropylene, nylon, Teflon®, Nomex®, and fiberglass.

GasPleat™ Quick-Change Series (JQC)

Versatile Phase Separation Filters

The Quick-Change series has been designed as an extension to the Jonell Systems GasPleat™ product line. The GasPleat™ cartridges are designed to remove rigid contaminants from dry natural gas streams.

Jonell Systems Quick-Change toolless cartridges are built to reduce maintenance downtime with design features like rounded end caps, wide handle grip, high durometer chevron gasket for a positive seal to avoid bypass and effective contaminant removal.

These cartridges can be easily installed without indexing reducing downtime.

Gas Coalescing Cartridges

Jonell Systems Gas Coalescing elements are available in a wide variety of materials and orientations to ensure our customers have complete control over their gas filtration process needs.

TRI-SHiELD Series (JRGC)

Vertical Reverse Flow Coalescer Cartridges

Designed for vertical coalescers used in coalescing applications such as compressor discharge, contactor protection, contactor discharge, these cartridges are perfect to remove difficult contaminants including fine aerosols and low surface tension liquids such as amines, glycol and lube oils.

TRI-SHiELD Series (JGCS)

Horizontal Multi-Stage Coalescer Cartridges

Jonell Systems TRI-SHiELD patented media JGCS single piece cartridges, are suitable for critical applications that require high coalescing efficiencies or in challenging applications with high dirt and high liquid loading including semi solids, iron sulphide and paraffins.

Twist-LOK™ Series (JGCP / JGCC)

Versatile Phase Separation Filters

Twist-LOK Filter’s versatile separation system offers superior contaminant removal and coalescing efficiency with the added feature of our Twist-LOK locking mechanism allowing the ability to customize filter and coalescer cartridges, as needed, to suit specific operating conditions. Designed to remove liquid and solid contaminants from natural and process gas, the assembled cartridge provides both a first stage “outside-to-inside” flow direction filter element and a second stage “inside-to-outside” coalescer element.

Now also available in TRI-SHiELD media.

Micro-LOK™ G Series (JPMG)

Coalescing Filter Elements

Designed for the removal of entrained low surface tension mist and aerosols, the Micro-LOK G Series Pleated Depth Vapor Phase Coalescing Filters is an industry work horse in reverse flow coalescing.

Available in hundreds of configurations and sealing types; you can trust the Micro-LOK G Series when an absolute 0.3 micron efficiency is critical.

Micro-LOK™ Series (JOS)

Coalescing Filter Elements

Micro-LOK JOS Air Oil Separator Coalescing Elements are designed to remove sub-micronic aerosols from a gas stream.

Most commonly used to remove lubricating oil aerosols in a compressor discharge.

Micro-DEP™ G Series (JMG)

Ultra-Fine Vapor Phase Coalescing Filter Elements

Micro-DEP G Series ultra-fine depth style micro-glass vapor phase coalescing filter elements are reverse flow elements designed for the removal of entrained low surface tensions mists and aerosols.

When absolute 0.3 micron efficiency is critical, you can trust Micro-DEP G Series.

JPEX™ Series

Conical Style Coalescing Cartridges

JPEX™ Series conical style elements coalesce extremely fine liquid particles from natural gas, such as lubricating oil downstream of a compressor.

The flow pattern through the element is from the “inside-to-outside, reducing the gas velocity as the droplets are being removed.

JPEX Series elements are available in various grades of high performance micro-fiberglass with hardware to suit specific applications.