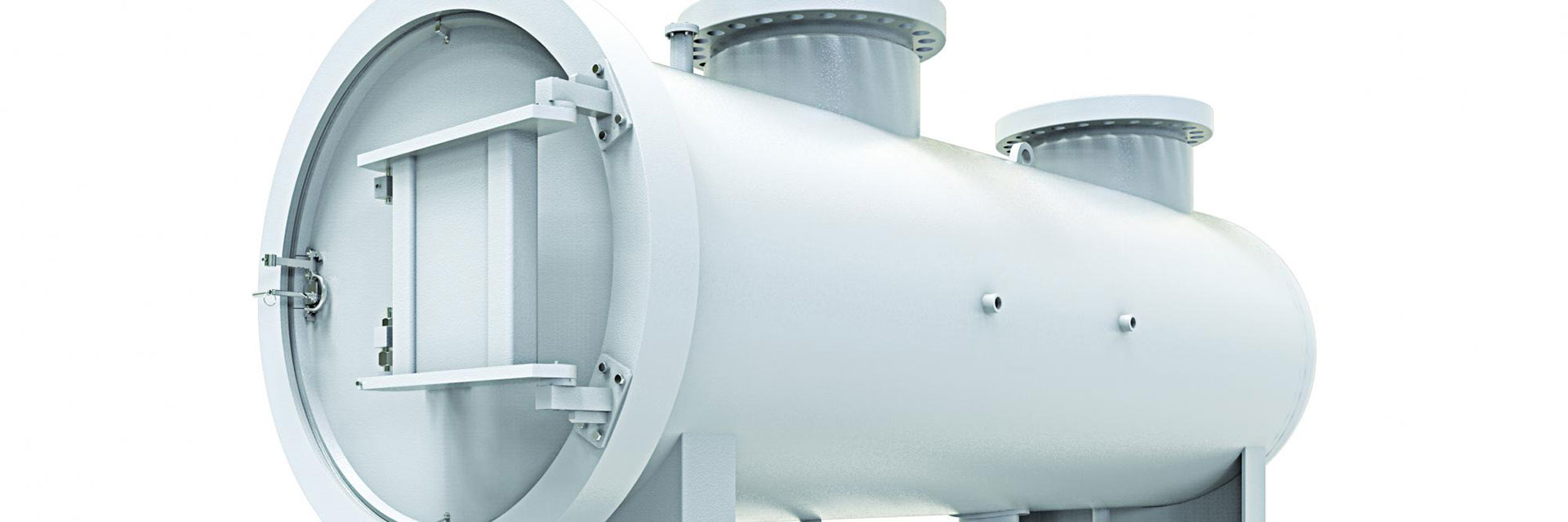

Gas Filter Housings

Gas Filter Housings – Engineered for Performance & Reliability

Jonell Systems’ gas filter housings set the industry standard for quality, durability, and operational efficiency. Designed to protect critical equipment and optimize process performance, our housings are built to ASME Code Section VIII Div. 1 and can be customized to meet international standards and specific application needs.

We recognize that no two processes are the same—which is why we collaborate closely with customers to engineer tailored filtration solutions that ensure maximum efficiency and reliability.

For applications that require an immediate solution, we maintain a stock of standard housings to help you minimize downtime and keep operations running smoothly.

Why Jonell Systems?

Industry-Leading Durability – Engineered for longevity in demanding environments

Application-Specific Customization – Designed to match your unique gas filtration requirements

Global Standards Compliance – ASME-certified with international code options

Fast Availability – Stock housings available for urgent needs

Get Expert Support on Your Filtration Needs

Need a gas filter housing solution? Speak with our team to discuss your requirements and find the best fit for your process.

Gas Coalescing

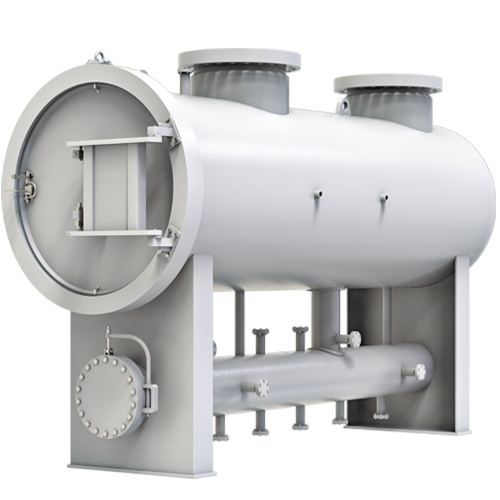

Sentinel Horizontal Gas Coalescer

SentinelTL™ with the customizable Twist-LOK™ filter elements is the only Horizontal Coalescer on the market with the flexibility to be applied in all critical protection applications from compressor suction and protection to final measurement and regulation stations. It can also be applied in cryogenic processing plants as pre-and post process protection. The key to this product is it is not hampered by turn down issues inherent in traditional Filtration.

__________

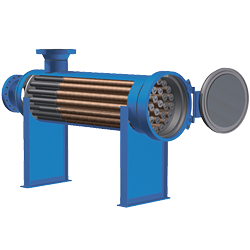

GR Series – Wet Gas Coalescer

The GR series reverse flow, wet gas coalescer removes compressor oil, trace hydrocarbons and water. It is not intended to remove particles or large amounts of water. This coalescer contains a large bottom sump area for the collected liquids, as well as a standard upper chamber sump.

GR series housings are configured vertically regardless of flow rate to utilize gravitational liquid removal benefits. These housings can be customized to customer specs including automation which is available for monitoring and dumping of collected liquids.

Gas Filtration & Separation

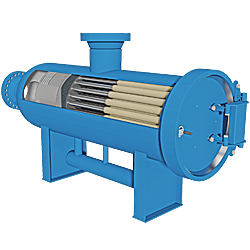

GD & GZ Series – Dry Gas Filter Housings

The GD and GZ series, forward flow, dry gas filter housings remove particulate contamination from dry gas including dust, dirt, sand and pipe scale. These filter housings are designed to filter fine particles from gases without excessive pressure differential build-up. Housings are available in vertical (GD series) or horizontal (GZ series) configurations and provide high flow rates at a low differential pressures.

__________

GW & GE Series – Wet Gas Filter Separators

GW series filter separators for wet gas, remove particles of dust, dirt, sand and pipe scale plus liquids, including water, natural gas liquids, and light hydrocarbons. These housings have a two-stage construction utilizing cartridges and a mist eliminator. Choose the vertical configuration GW Series for low-volume applications. Also available is the GE series (horizontal housing configuration) for high-volume applications.

Scrubbers & Separators

Wire Mesh

- Deliver excellent results over a broad range of gas/liquid separation tasks

- Highest separation efficiency

- Lowest installation costs

Standard & Double Pocket Vanes

- Handles higher throughputs than mesh technology with a more robust construction.

- Handles viscous liquids

- Operates well in fouling service

- If contaminants deposit on the vane blades, we can install the vanes with spray nozzles to clean the blades during operation

Cyclonic Tube Separators

- In-line and multiccyclone separators provides protection down to the 3-5μm range of liquids and associated solids

- Overall removal efficiency of 99.9% of normal pipeline contamination

- Robust construction can operate in conditions where normal separators cannot, and where momentary flow rates above design conditions need to be tolerated without replacing filters continually.